Better informed. Better results.

Are you in the middle of planning your printed matter? Find out more about our equipment and technology here. We can also offer detailed advice on data transfer. Feel free to get in touch with us at any time if you have any questions or would like paper and processing samples.

Digital blueprint.

To design production workflows securely and time-efficiently, we work with the KODAK InSite Prepress portal, an interactive web portal for uploading and approving complete print jobs. This tool facilitates the print production control and thus the optimum use of printed sheets and printing time over a single user interface. In this way, customers can view, update and approve their orders via a desktop computer or mobile device – round the clock and from anywhere.

All this makes the KODAK InSite Prepress portal a powerful tool for online collaboration, with which potential problems can be identified early in the production process and errors avoided. It helps to save valuable time and to centralise all of the tasks involved in the pre-press stage.

Data receipt.

Please send us your data (up to 20 MB) by email to repro@lanarepro.com. In the case of larger file sizes we recommend that you send your data via www.wetransfer.com. You can send your data to us in a variety of formats. Print files that must not be altered should be sent in PDF format. Your attention is drawn to the fact that additional costs may be incurred if “open files” are used. We therefore request that you always append colour-consistent proofs (Fogra certified) to your print files. Print files or PDFs that are printed by our company must always be produced according to established standards and where necessary coordinated with the relevant employees in our technical department.

Supply of data by Lanarepro to third parties:

Lanarepro GmbH, which is based at Peter Anich Strasse 14, I-39011 Lana (BZ), hereby gives notice of the fact that in the case of the supply of data for further processing on MAC or PC and production in the case of Computer to Film, Computer to Plate or Computer to Press, liability claims are limited.

All data (open files, PS files, PDF files etc.) that are stored on data carriers or sent via FTP upload, WeTransfer or email, will be checked and saved with the greatest of care by the specialists at Lanarepro.

Where data carriers may be faulty, or transmission or data errors are caused by technical issues, and in the event of transport damage or archiving errors, Lanarepro GmbH cannot accept any liability.

Colour profiles

As standard we use the ECI Offset profile, see www.eci.org.

Depending on paper type we prefer:

PSO Coated v3 (FOGRA 51) for coated papers

PSO Uncoated v3 (FOGRA 52) for uncoated natural papers

However the following may also be used:

PSO Coated v2 (FOGRA 39) for coated papers

PSO Uncoated v2 (FOGRA 47) for uncoated natural papers

Please specify which profile was used when creating the data in the file description.

Wichtig: If other colour profiles are used when creating the data, we must be expressly notified of this fact. Otherwise there may be considerable differences in the colours when printed, for which we cannot accept any responsibility.

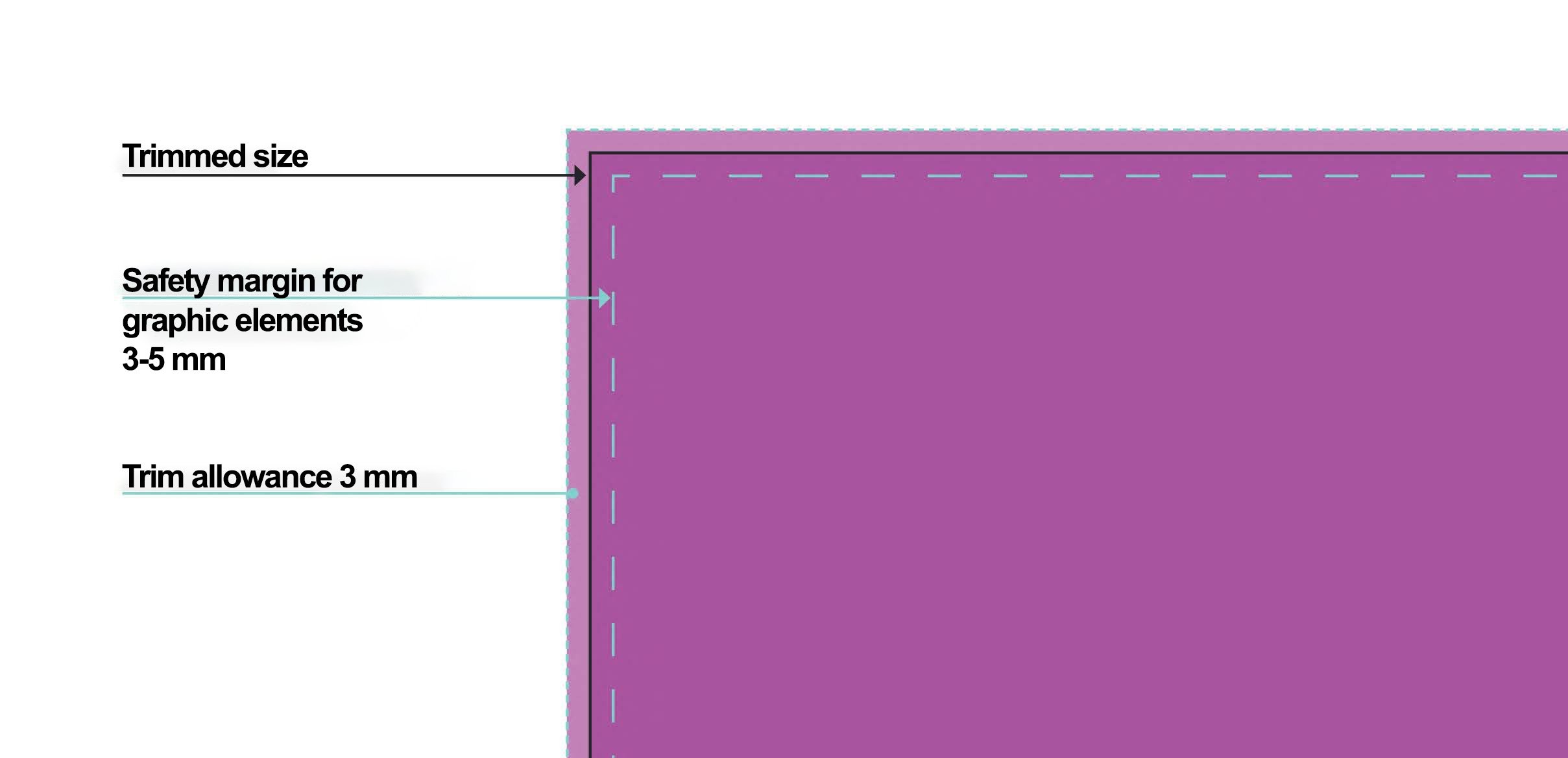

Trim allowance / bleed

The trim allowance/bleed is a required paper or image margin of 3 mm, which extends beyond the trimmed size of the printed matter.

If there are images or areas in your printed product that extend as far as the margin, we require what is known as a trim allowance/bleed, that is the image or the areas must extend 3 mm over the trimmed size, to avoid unsightly white borders around the edges of the printed image.

Important graphic elements or text should be at least 3 mm but ideally 5 mm away from the trim line.

PRE-PRESS STAGE

4 iMac‘s (graphic and layout)

3 iMac‘s Mac Pro

2 Windows Work-Stations

Textur-Scanner Cruse Reprodecor CS ST

2 Spectroproofer EPSON P5000

Plotter Epson 9880 for Formproofs and Posters

KODAK Magnus 800

Cutter Esko Kongsberg

Software

KODAK InSite Prepress Portal-System

KODAK Prinergy Workflow

Adobe Creative Suite

Cumulus Professional Enterprise

GMG Colormanagement Fogra-Standard

Heidelberg Prinect Pressroom-Manager + MIS Connector

Esko ArtiosCad

Digital Printing

KONICA-MINOLTA ACCURIO PRESS C6085

Papers from 61 - 400 g/m² are automatically printed on both sides

Booklets DIN A4 or DIN A5 are finally cut inline

Up to a maximum of 200 pages (depending on the paper)

Paper weight from 52 to 400 g/m²

Max. Paper format 330.2 x 487.7 mm

Max. Print format: 477.0 x 320.0 mm

Booklets can be stapled with either 2 or 4 staples

Booklets can be produced with a square spine

Banners, menus, envelopes - up to a paper format of 76.0 x 33.0 cm - on papers up to 300 g/m² in straight and reverse printing

Printed matter can be personalised (images, text, contact persons, addresses)

Printing also possible on waterproof, synthetic materials

Large format printing LFP

Fujifilm Acuity Prime 30 - LED-UV printing system

Print size: 2540 x 1274 mm

Max thickness of substrates: 51 mm

RIP: Colorgate

Max. Print speed 150 m²/hour

Printing inks: Greenguard Gold

Colours:

CMYK

White colour

Varnish (matt and glossy)

Primer

Offset printing

HEIDELBERG XL 106 4 + L

Maximum sheet format: 750 x 1060 mm

Maximum print format: 740 x 1050 mm

Printing plate format: 811 x 1055 mm

Maximum printing speed: 18,000/h

Substrate: 0.03 - 1.0 mm

Colour measurement: inline spectral

Dispersion coating unit

Further processing

Polar guillotine 115

Polar Transomat 1 ER 130-4

3 folding machines

Palamides - Automatic delivery

Muller Martini saddle stitcher with cover station, 6 stations with ASIR optical sheet inspection at all stations